Difference between bolt and screw and stud that we should know more about. difference fasteners with different sharps, used for different industries.

screws and bolts are well-known fasteners. They are mainly used in manufacturing. They all have different functions and have different shapes and appearances. Here, we are trying to understand the difference between bolts, screws, and studs.

How do you think the wheels of your car are connected to the body of your car? This is the ins and outs! Screws, bolts, and studs. These are the most commonly used items, but we hardly noticed them and benefited a lot from these seemingly harmless little devices.

Difference between bolt and screw and stud – screws

A screw can be defined as an inclined surface wrapped around a nail, characterized by a spiral ridge. In other words, it is a long metal shaft with threads along its length. It also has a twist, you can use a screwdriver to turn the screw.

Screws shap

Screws usually have a specially shaped head. The size and shape of the head determine the size of the tool used to rotate or drive the screw. Commonly used tools are wrenches and screwdrivers.

The lower part of the head is a rod that can be fully or partially threaded. The thread is a spiral cylindrical or conical structure. The upper part of the ridge is called the ridge, and the lower part is called the root. The distance from the crest of one thread to the next thread is called the pitch.

Screws are tightened by turning the tool clockwise or counterclockwise and are usually used to connect materials without holes. The most common types of screws in manufacturing are concrete screws, set screws, drywall screws, and mirror screws.

Screw strength

The strength of the screw depends on the width of the threads and the distance between them. However, the greater the number of threads, the greater the number of rotations required to set the screw. In addition, if the distance between successive threads is greater, more force must be applied to the tool during rotation.

Screws are widely used in many applications. From furniture to motorcycles, from air conditioners to children’s remote control cars.

Difference between bolt and screw and stud – Bolt

A bolt is a threaded external fastener used to insert into a hole in an assembled part. Bolts are usually designed to be tightened or loosened with nuts.

Generally, bolts have a uniform circular cross-section, threads have a spiral structure, and have a smaller pitch than screws and studs.

Unlike bolts, bolts do not have a tapered shank. Parts fixed with bolts have greater strength than parts fixed with bolts. The bolts and nuts act together on the application and are tightened where the torque is applied. Some commonly used bolts are carriage bolts, plow bolts, and rail bolts.

The reliability and durability of bolted parts are much higher than bolted parts. Bolting applications include flange gaskets or fixed objects made of metal materials. In addition, bolts are used not only for machinery but also for plumbing and electronic products. Bolts are an integral part of the reliability of equipment and components.

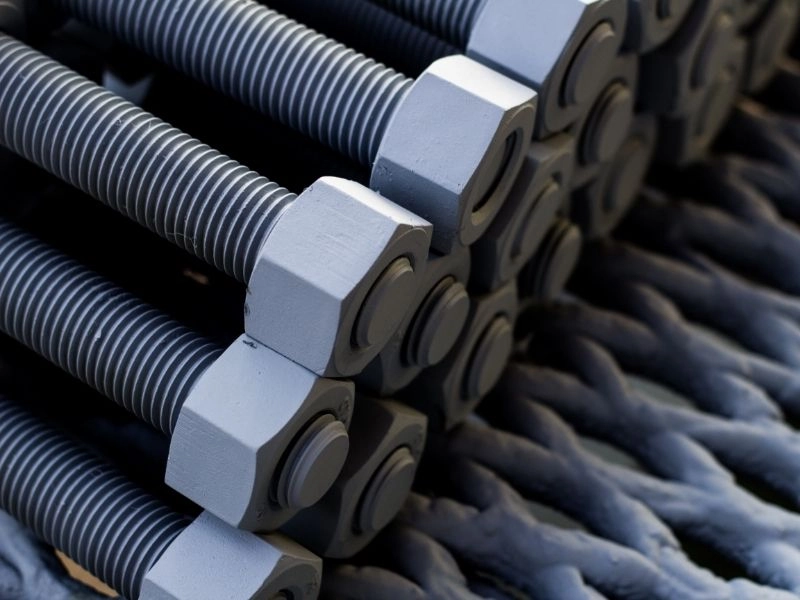

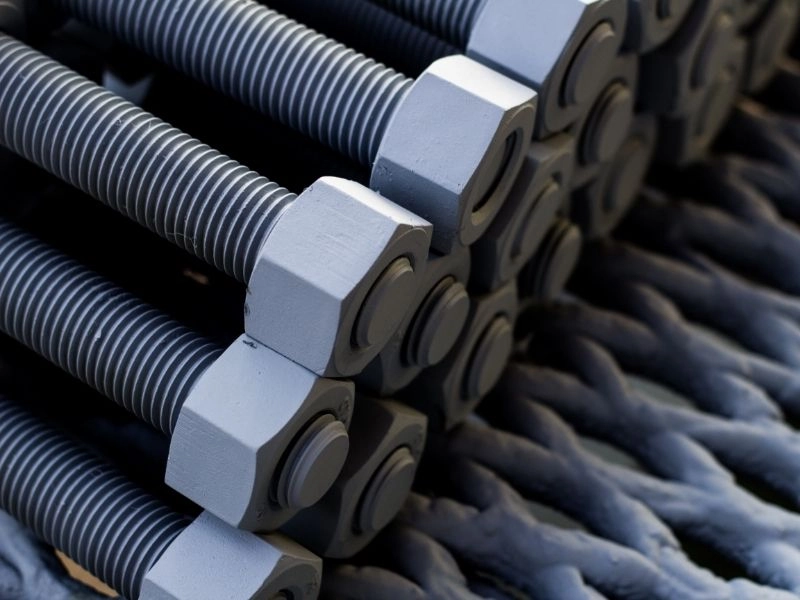

Difference between bolt and screw and stud – stud bolts

The stud bolt is a metal rod or shaft with threads on both sides. Usually, the rod is longer, but the size may vary depending on the requirements. Studs are headless fasteners with external threads. In other words, we can say that one end of the stud is connected to the tapered part and the other end is connected to a standard nut.

Unlike screws and bolts, studs do not have a head that needs to be tightened. When installing the bolts, no external force is required to tighten them, and the bolts can be installed manually.

Stud is bigger than bolts and screws

Studs are relatively larger than bolts and screws, so they go deeper into the threaded holes for additional applications, actually close to the untightened part of the thread. Bolts have two forces applied to them: rotational force and linear force will give inaccurate torque readings. No rotational force is applied by the stud, so we can get a more accurate reading.

Types of studs

There are three main types of studs: fully threaded studs, threaded end studs, and double-ended studs. Depending on the application, the bolts are made of various materials to meet operational requirements. Since the stud threads are not stretched, they can generate repeatable clamping forces, so they have a longer life.

Studs are usually used to fix cable ties. The quality of the connecting flange is determined by the hole on the flange diameter, and the length of the bolt is determined by the flange type and pressure rating.

The bolt prevents fluid from leaking through the holes in the machine. They are also used to assemble heavy materials such as turbines, fuel tanks, cylinder heads, and gaskets.

Bottom line-the difference between bolts, screws, and studs It is important to note that each of them has a different purpose, and you need to determine which one is best for the project you choose.

Also, before choosing to use it for a project, make sure you understand the strength and material of bolts, screws, or bolts. Before choosing it, you need to consider how it will affect or improve the overall performance of the project.