In an engine, metal parts slide and operate violently against each other under high heat and hard conditions. Naturally, sliding (rubbing) parts are gradually reduced or deformed, even if they are steel parts. This is why lubrication is so important, and engine oil plays an important role. Even if you think you are taking good care of the oil, the condition of the engine will deteriorate over the years of riding. In this case, we decided to request an internal combustion machine shop to recondition the disassembled cylinder head as much as possible to its best condition. The words used there were “seat cutting” and “head surface grinding”.

What kind of work is that?

- The width of the contact surface between the valve seat and valve face is important

- Request precision reproduction at a professional store for internal combustion machine machining.

- The 4-valve 2-cylinder of Kawasaki W650 is also regenerated with high precision.

The width of the contact surface between the valve seat and valve face is important

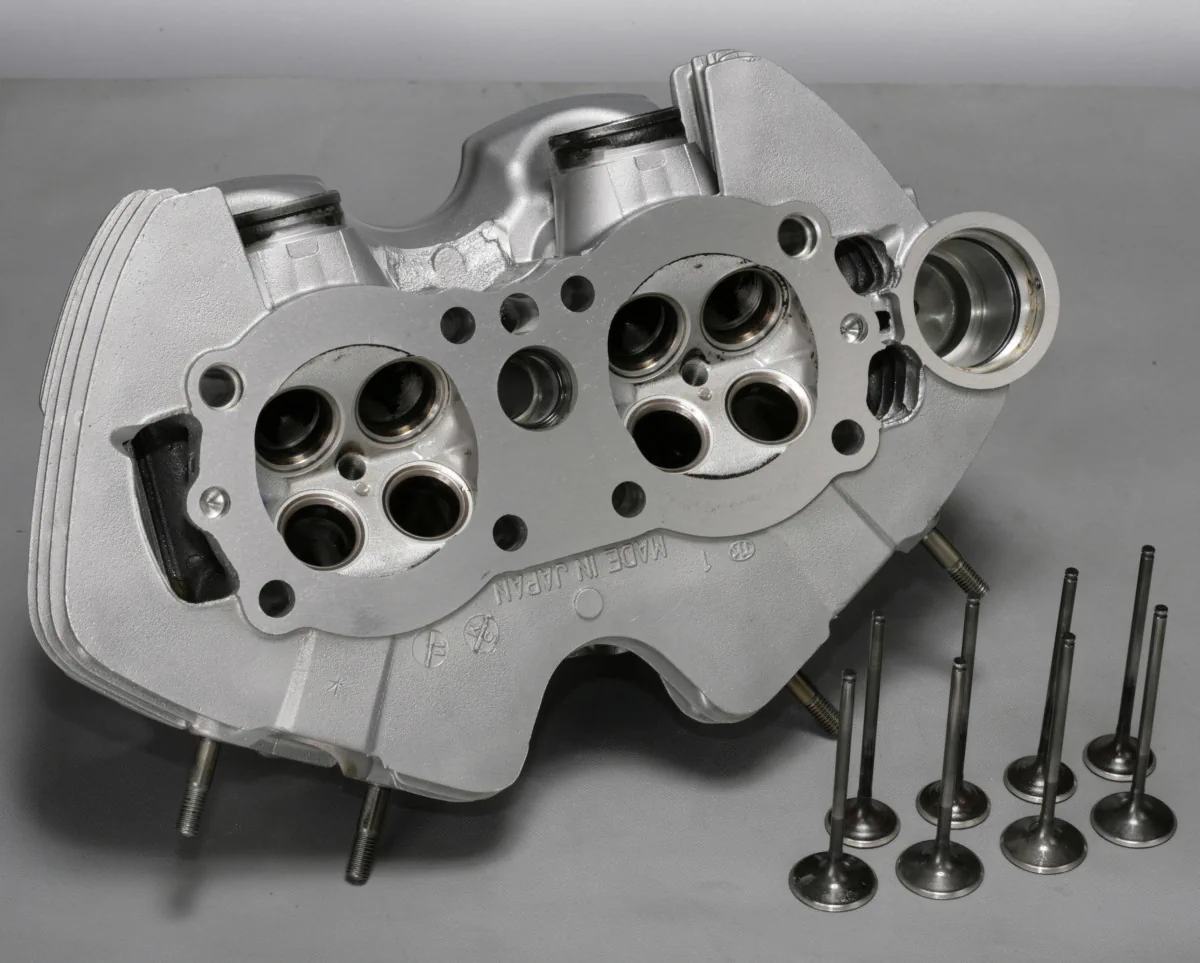

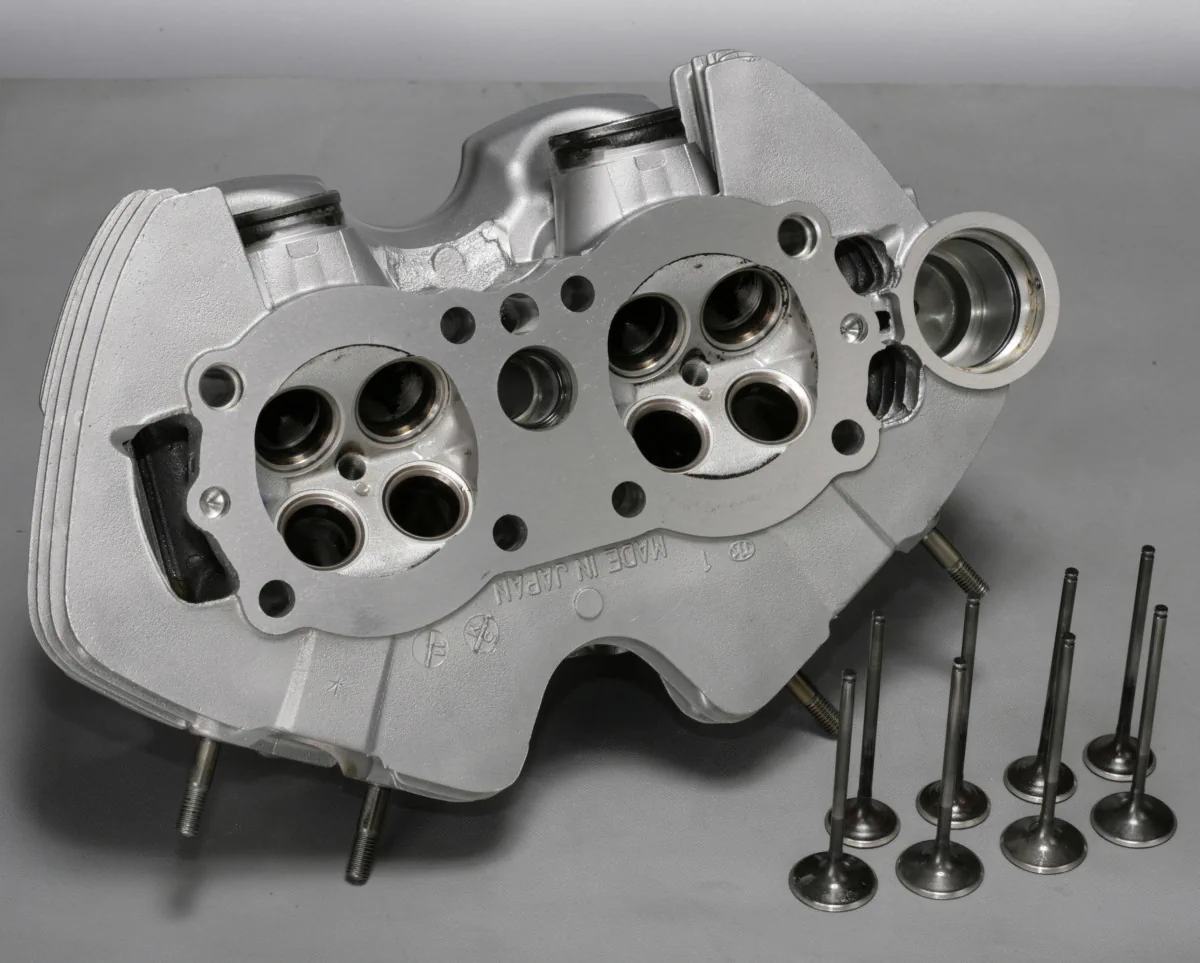

The combustion chamber in the cylinder head has ports that receive the valves. The part that directly receives the valve is called the valve seat (ring-shaped press-fit part), and the part where the umbrella valve hits the valve seat is generally called the valve face. After many years of operating, this valve hit becomes wide with a sticky hit. By correcting such a wide contact, intake and exhaust gases flow smoothly, compression is increased, and engine power is surely improved. Valve seat cutting is the process of reshaping the valve seats in the cylinder head, and valve face machining is the process of polishing and resurfacing the concave surfaces of the valve faces due to the wide contact. Since the disassembled intake valve had a slightly wider contact width, the valve face was polished using a valve polishing machine manufactured by KWIK-WAY of the United States. The machine is precise and easy to use, but because it is made in the U.S., it is not compatible with small-diameter umbrella valves. Therefore, iB Inoue Boring has modified the machine so that it can be used with small-diameter umbrella valves.

Request precision reproduction at a professional store for internal combustion machine machining.

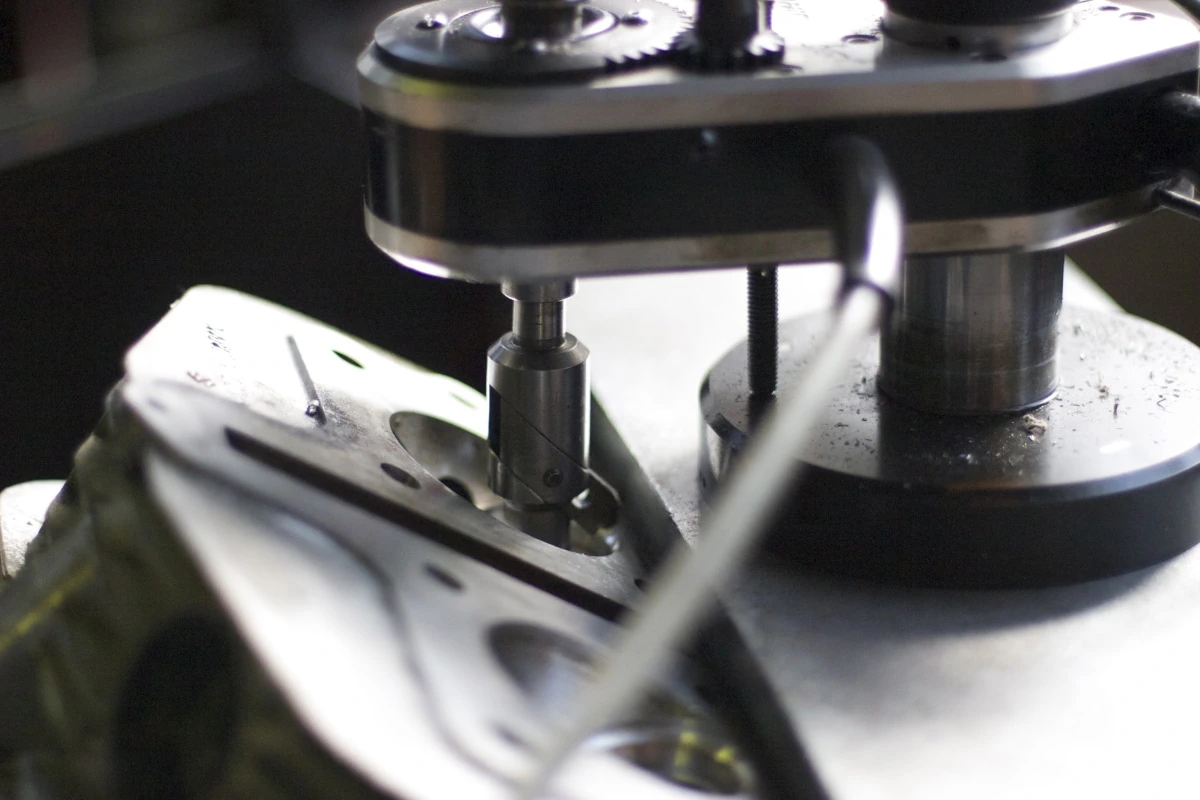

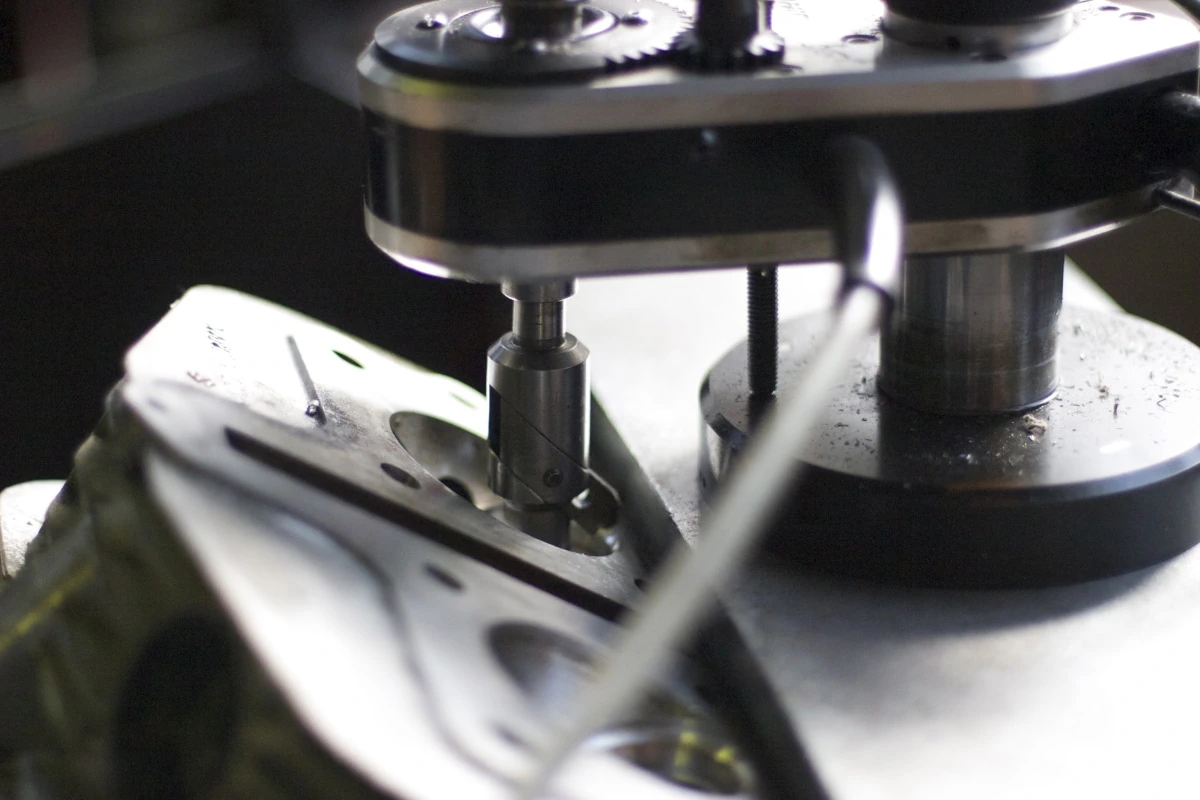

iB Inoue Boring in Kawagoe City, Saitama Prefecture, which cooperated in the photo shoot, uses a machine called a valve seat refacer made by MIRA of Switzerland to process and rebuild cylinder heads. The unique centering mechanism quickly and accurately measures the center of the valve stem for various valve guides. The machine’s high workability and precision machining capability are its outstanding features. The on-board vacuum test equipment can also be used to quickly inspect for pressure leaks. Instead of using sheet cutters for inside cutting, outside cutting, and bite-surface cutting, the company has introduced a wonderful machine that can achieve both short time, high precision, and repeatability by using a single cutter blade to achieve the optimum sheet-cut shape.

The 4-valve 2-cylinder of Kawasaki W650 is also regenerated with high precision.

The Kawasaki W650, with four valves per cylinder, has been ridden since new, and many owners have already put more than 50,000 kilometers on it. Many owners who continue to ride the same bike often don’t notice the gradual decline in engine power. Even though the engine starts well, there is no white smoke coming out of the muffler, and idling is stable, the engine power is surely decreasing after 50,000 km of riding. At the first run after internal combustion engine modification, “Eh, it’s as torquey as if it was bored up! That’s how it often feels.

The tight fit between the intake and exhaust valves and valve seats is more vital than anything else for a 4-stroke engine.