An important step you must take after determining your compressed air requirements is the distribution piping for the system. The piping will be the “veins” that connect your entire facility to the compressor. Before installing pipe, it is important to consider how the compressed air will be consumed at the point of use. In order to ensure optimal performance of any compressed air operated device, you must ensure sufficient compressed air flow is delivered. Simply put, inadequate air flow won’t allow you to get the job done.

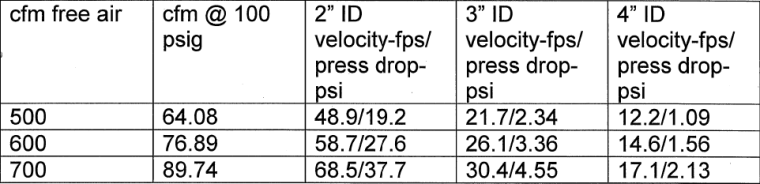

Pressure drop through the pipe is caused by the friction of the air mass making contact with the inside walls of the pipe. This is a function of the volume of flow through the pipe. Larger diameter pipes will result in a lower pressure drop, and vice versa for smaller diameter pipes. The chart below from the “Compressed Air and Gas Institute Handbook” provides the pressure drop that can be expected at varying CFM for 2”, 3”, and 4” ID pipe.

Once you’ve determined the appropriate piping size for your system, you’ll need to consider the different materials that are available. Some different materials that you’ll find as options are: steel piping (Schedule 40) both with or without galvanizing, stainless steel, copper, and even some plastic piping systems are available.

Plastic piping is not generally recommended to be used for compressed air. Some lubricants that are present in the air can act as a solvent and degrade the pipe over time. PVC should NEVER be used as a compressed air distribution pipe. Take a look at this inspection report an automotive supply store received fines totaling $13,200 as a result of an injury caused by shrapnel from a PVC pipe bursting. However, there are some composite plastics that are suitable for use with compressed air. PVC is most certainly not one of them.

Steel pipe is a traditional material used in many compressed air distribution systems. It’s strong and durable on the outside and is a familiar material for many to work with. Its strength comes at a price, steel pipe is very heavy and requires anchors to properly suspend it. Steel pipe (not galvanized) is also susceptible to corrosion. This corrosion ends up in your supply air and can wreak havoc on your point-of-use products and can even contaminate your product. While galvanized steel pipe does reduce the potential for corrosion, this galvanizing coating can flake off over time and result in the exact same potential issues. Stainless Steel pipe eliminates the corrosion and rusting concerns while still maintaining the strength and durability of steel pipe. They can be more difficult to install as stainless steel pipe threads can be difficult to work with

Copper piping is another potential option. Copper pipe is corrosion-free, easy to cut, and lightweight making it easy to suspend. These factors come at a significant increase in costs, however, which can prevent it from being a suitable solution for longer runs or larger ID pipe installations. Soldering of the connecting joints can be time consuming and does require a skilled laborer to do so.

Another lightweight material that is increasingly more common in industry is aluminum piping. Like copper, aluminum is lightweight and anti-corrosion. They’re easy to connect with push-to-lock connectors and are ideal for clean air applications. Aluminum pipe remains leak-free over time and can dramatically reduce compressed air costs. While the initial cost can be high, eliminating potential leaks can help to recoup some of the initial investment.

When designing and maintaining your compressed air system, pressure measurements should be taken across varying points to identify (and fix) any issues before they create a greater problem down the road. According to the Compressed Air Challenge, these are the places you should take regular pressure measurements to determine your system operating pressure:

- Inlet to compressor (to monitor inlet air filter) vs. atmospheric pressure

- Differential across air/lubricant separator

- Interstage on multistage compressors

- Aftercooler

- At treatment equipment (dryers, filters, etc.)

- Various points across the distribution system

- Check pressure differentials against manufacturers’ specifications, if high pressure drops are noticed this indicates a need for service

*More recent compressors will measure pressure at the package discharge, which would include the separator and aftercooler.

Once you’ve taken these measurements, simply add the pressure drops measured and subtract that value from the operating range of your compressor. That figure is your true operating pressure at the point of use.

If your distribution system is properly sized and the pressure drops measured across your various equipment are within specifications, any pressure drop noticed at the point of use is indicative of an inadequate volume of air. This could be due to restrictive fittings or undersized air lines, hose, or tube. Check that the point of use product is properly plumbed to compressed air per the manufacturer’s specifications.

EXAIR Products are designed to minimize this pressure drop by restricting the flow of compressed air. The more energy (pressure) that we’re able to bring to the point of use, the more efficient and effective that energy will be. If you’re looking to improve on how compressed air is used within your manufacturing processes, give us a call.

Tyler Daniel

Application Engineer

E-mail: TylerDaniel@EXAIR.com

Twitter: @EXAIR_TD

Image courtesy of Tampere Hacklab via Flickr Creative Commons License