Maximizing the performance and longevity of your 200104-00001A track roller involves proper maintenance, careful operation, and timely interventions. Here are some strategies to ensure you’re getting the best out of your track roller:

1. Regular Inspections

Visual Checks

- Frequent Inspections: Regularly inspect the track roller for signs of wear, cracks, or misalignment. Early detection of issues can prevent more significant problems down the line.

Monitor Alignment

- Track Alignment: Ensure the track roller is correctly aligned with the tracks. Misalignment can lead to uneven wear and reduced efficiency.

2. Proper Maintenance

Lubrication

- Follow Guidelines: Adhere to the manufacturer’s recommendations for lubrication. Regularly check and apply grease to minimize friction and wear.

Cleanliness

- Keep It Clean: Remove debris and dirt from around the roller and tracks to prevent premature wear. A clean environment contributes to better performance.

Track Tension

- Regular Adjustments: Monitor and adjust the track tension to ensure it remains within the recommended range. Proper tension reduces stress on the roller.

3. Optimize Operational Practices

Operator Training

- Skilled Operators: Ensure that operators are trained in the proper use of machinery. Skilled operation prevents unnecessary strain on the track roller.

Smooth Movements

- Controlled Operation: Encourage operators to use smooth and controlled movements when operating the machinery. Jerky movements can cause excessive wear on the roller.

4. Seek Quality Parts

Genuine Components

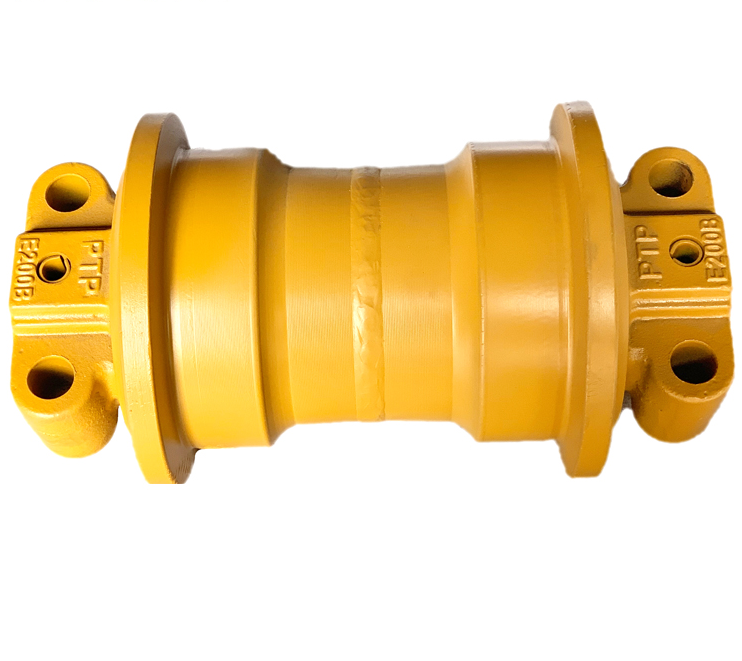

- Use OEM Parts: Whenever replacements are necessary, opt for original equipment manufacturer (OEM) parts like the 200104-00001A track roller. Quality parts ensure better compatibility and performance.

5. Monitor Performance

Use Diagnostics

- Track Performance Metrics: If your machinery is equipped with diagnostic tools, use them to monitor the performance of the track roller and other components. Look for signs of inefficiency.

Listen for Unusual Noises

- Auditory Checks: Pay attention to any unusual sounds during operation. Noises may indicate problems with the track roller or related components.

6. Troubleshoot Issues Promptly

Address Problems Early

- Immediate Attention: If you notice any signs of wear, noise, or misalignment, address the issue promptly to prevent further damage.

Consult Professionals

- Expert Assistance: If issues persist, consult with a technician or equipment specialist for an accurate diagnosis and repairs.

7. Schedule Regular Maintenance

Maintenance Routine

- Follow a Schedule: Establish a regular maintenance schedule to check the track roller and related systems. Consistent care helps to extend the lifespan of the component.

8. Document Maintenance Activities

Keep Records

- Maintenance Log: Maintain a log of inspections, maintenance activities, and replacements. This helps track the history of the track roller and can guide future maintenance decisions.