With all the options when it comes to air compressors, I wanted to take a deeper diver into Single acting Reciprocating compressors and see why they are so popular across all industry.

First, What is a Single acting Reciprocating air compressor, and how does it work? A single-acting compressor is a type of air compressor that uses only one end of the piston for the suction and compression. So the first stroke of the piston sucks the air inside the compressor while the air compression occurs in the second stroke.

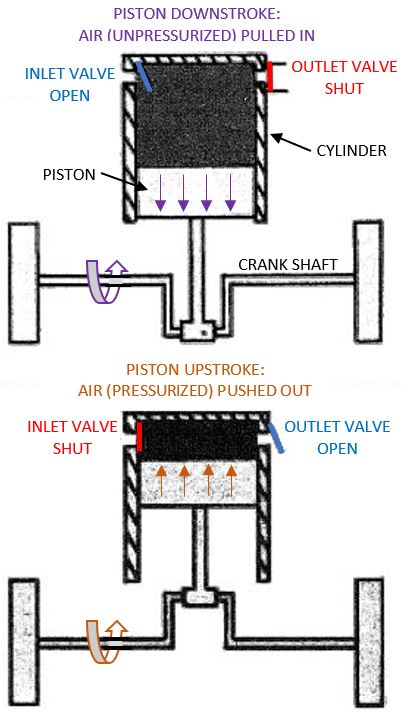

To explore the internals a bit closer, a mechanical linkage, or connecting rod, is attached to a piston and a crankshaft. For every rotation of a motor, the piston will move up and down. Air is being drawn into the cylinder and then compressed. The volume of the cylinders, the number of cylinders, and the rotations per minute will determine the amount of compressed air that can be produced. The advantages with reciprocating compressors are that they can produce high pressure, compress different types of gases, and have a cheap and rugged design. The disadvantages would be high vibration and noise levels as well as being oversize as compared to capacity. (See the photo below)

Let’s expand on the advantages and disadvantages a bit to see if that explains the heavy use of this style air compressor!

Advantages

- Cost! Single acting Reciprocating air compressors just cost less than other styles of air compressors!

- They are typically easy to maintain.

- They work great for medium duty applications

- They require less traveling of the compressed air.

Disadvantages

- The piston only works in one direction at a time

- The piston spring takes up space limiting the cylinders working stroke.

- They are less efficient than centrifugal type compressors

No matter the type of air compressor that you use, they are very expensive to use. Air compressors are considered to be the fourth utility within a manufacturing plant. To help use it efficiently and safely, EXAIR offers a range of products to clean, cool, blow, clean, conserve, and convey. This would include our Super Air Knives, Super Air Nozzles, Safety Air Guns, Cabinet Coolers, and much more. If you want to save energy, increase safety, and cut overhead costs, you can contact an Application Engineer at EXAIR. We will be happy to help.

Jordan Shouse

Application Engineer

Send me an Email

Find us on the Web

Like us on Facebook

Twitter: @EXAIR_JS

Compressor internals image courtesy of h080, Creative Commons License.