Slides are rated by load but what does this mean?

Drawer slide manufacturers always give a maximum load rating for their products and you may be wondering what this means. This is the maximum load that a pair of slides can carry, but only IF you mount them as instructed and don’t exceed their cycle rating. The stated load ratings are a gross load, so don’t forget to add the weight of the drawer construction materials to your calculations.

‘Cycle rate’ is another term that we should explain. When slides are tested they are set up in a test rig with a drawer, or in their application environment and ‘cycled’ in and out a number of times. One cycle

= a complete open and close.

All our products are subjected to a static load test at full extension of the sliding elements. The load applied will typically be at least twice that of the dynamic load test. This means the slide will have a 100% static load safety factor in the extended position.

The cycle test is a dynamic load test. Different cycle rates are used depending on the type of slide and the expected application. For example, in

applications for the Industrial and electronic market sector, the cycle rate will typically be between 2,000 and 10,000 cycles and for the furniture market sector, the cycle rate will typically be between 50,000 and 80,000 cycles.

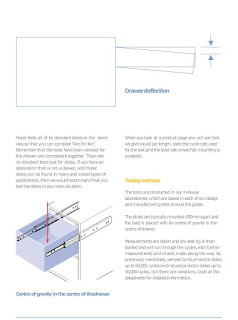

Deflection of the drawer and sliding element are measured during the dynamic test phase and this is correlated to the load and number of test

cycles completed. Din 68 858 details the allowable percentage of the extension this deflection can be.

#drawerslides #slides #telescopicslides #ballbearingdrawerslides #heavydutydrawerslides