The meter itself is mounted and secured to the bracket via a rubber damper that serves as a cushion.

If this damper rubber deteriorates, the meter will not stay in place even when tightened, resulting in a constant rattling condition, or conversely, it may lose all elasticity and become rigidly mounted. If this happens, the meter is directly subjected to driving vibrations, and the meter, an expensive and important precision component, can fail in no time at all.

Here, we will give you a lecture on maintenance techniques to avoid failure by paying attention to the condition of the meter mounts and surrounding parts.

- Most important damper-mounted type

- Be careful with meter cables that are not compatible with the OEM.

- Inner cables unplugged, cleaned, and greased

Most important damper-mounted type

The damper rubber is in place and not skinny, which is the natural condition. The correct tightening tension of the damper mount is obtained when the collar is in place, not at the deadline. If this collar is lost and fixed in a closed condition, it will cause meter failure, so be careful.

Be careful with meter cables that are not compatible with the OEM.

Special care must be taken when replacing meter cables. When replacing a meter cable that is not an OEM part, or when replacing a part for another model even if it is an OEM part of the same manufacturer, the protruding dimension of the inner cable must be checked. If the inner cable protrudes too much, the cable end will be pushed inside, either on the meter side or on the meter gear side, and this will cause problems. When using an external meter cable, thoroughly check and inspect the amount of protrusion. In particular, the meter side can easily fail if the cable is pushed in even a little bit, so check the amount of protrusion carefully before assembly.

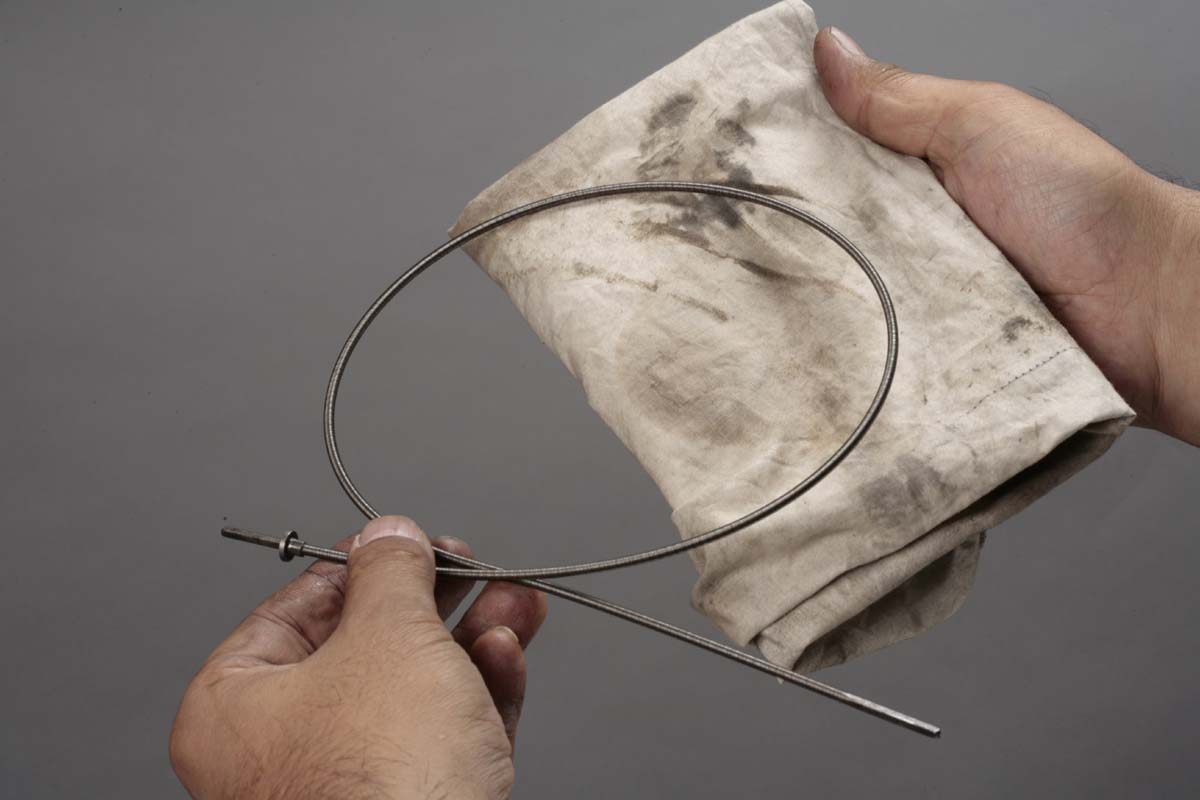

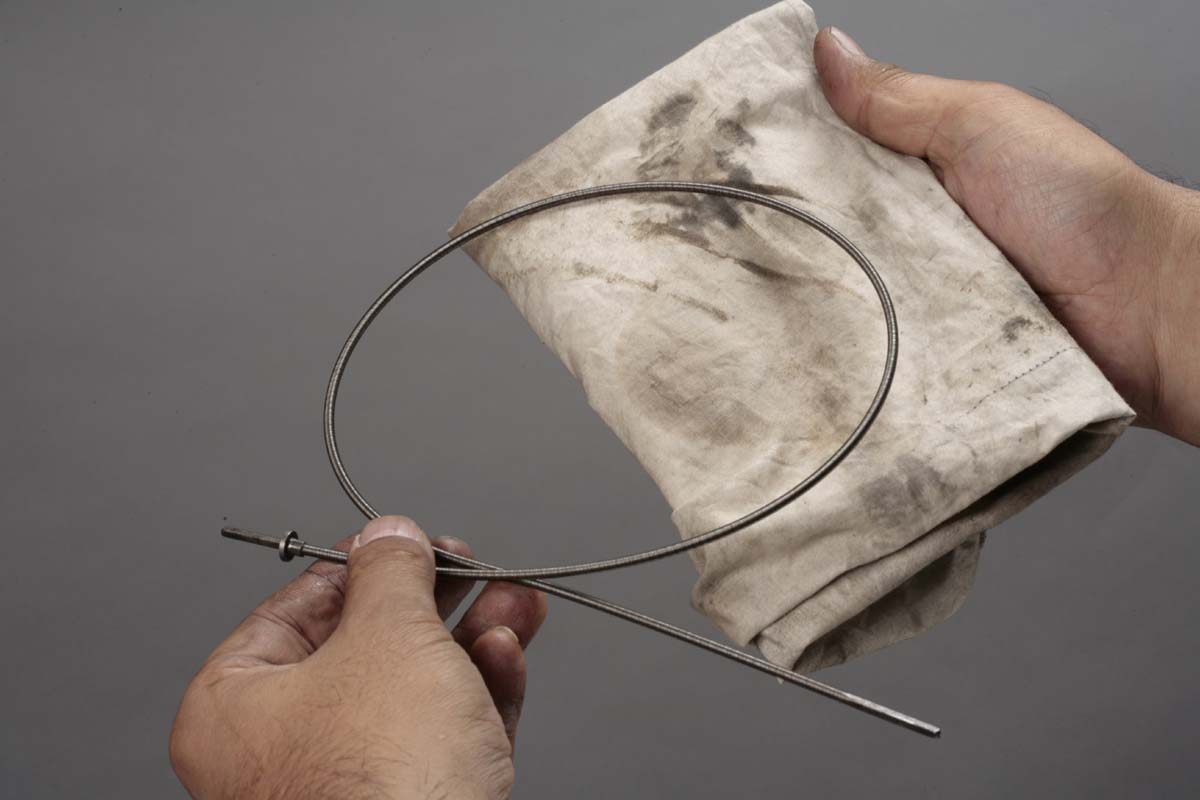

Inner cables unplugged, cleaned, and greased

If the meter cable is in poor condition, with a partial break, or if one of the cables is broken and sticks out like a spike, the meter pointer may move jerkily. To maintain the condition of the meter, disassemble the meter cable periodically, clean and blow air inside the cable, and grease up the cable.

It is also important to know that the meter cable routing is extremely important. If the cable gets caught in the tank, light stay, or other parts along the way, it may cause irregular vibrations to be transmitted to the meter itself, resulting in incorrect movement of the indicators in some cases. Soak the removed inner cable in kerosene or gasoline to wash off the dirty grease, blow air thoroughly, and then apply high-performance grease firmly to the inside of the spiral wire so that it is pressed into the inside of the spiral wire as well.