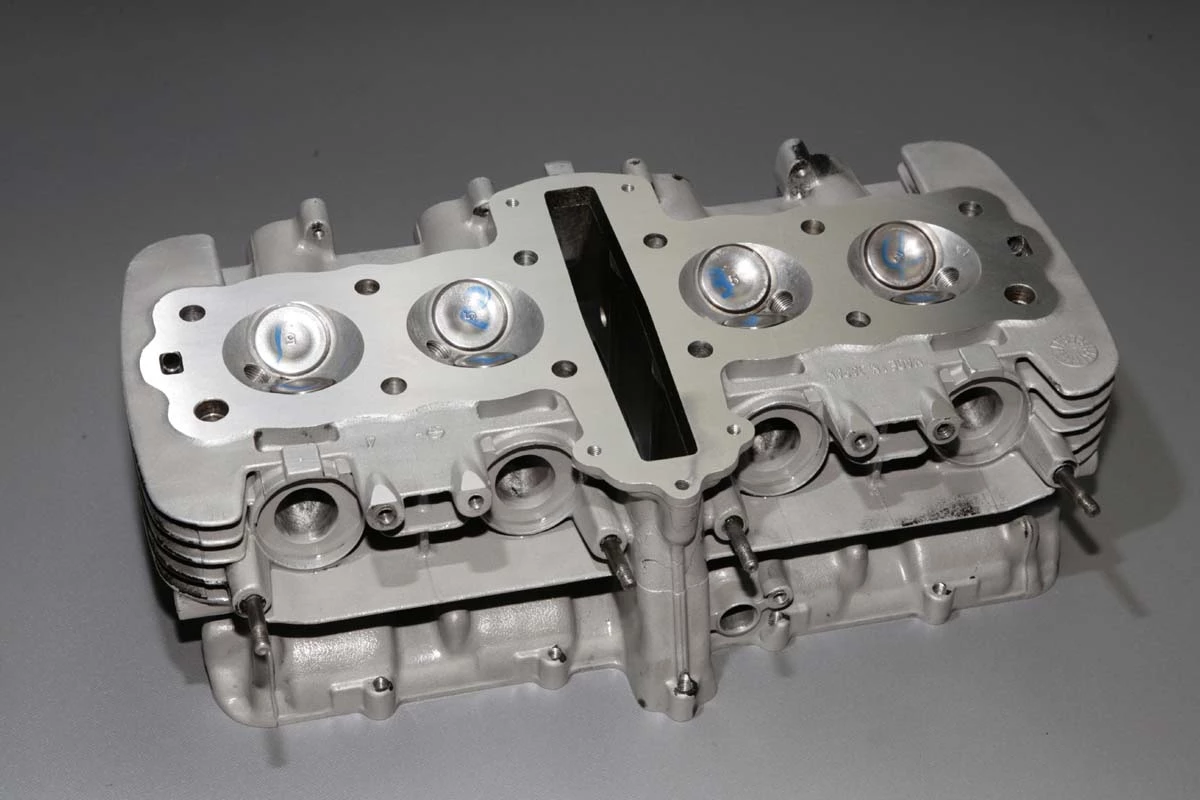

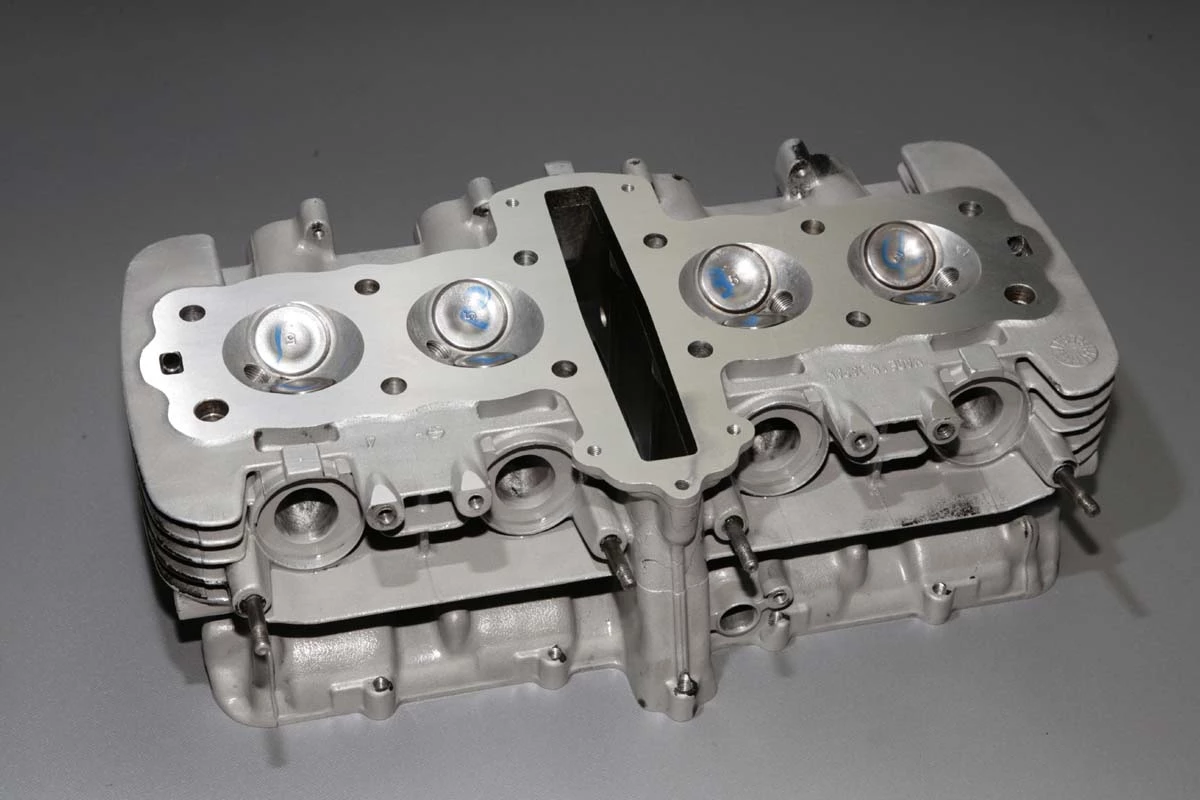

Whether it is a 4-cylinder multi-cylinder engine or a single-cylinder engine on a moped, the cylinder head is a major determinant of whether a 4-stroke engine is in good shape or not.

We often hear the term “overhaul” used to describe the overhaul of the engine waist, but here we will focus on the internal combustion machining of the cylinder head, which is the key component of the engine waist, or in other words, the repair work that is done when the cylinder head is disassembled.

- Intake and exhaust valve condition is the lifeline

- Face polishing to improve valve hit

- Seat cut to adjust the width of the valve hit

- Clear visual confirmation using red lead

Intake and exhaust valve condition is the lifeline

The key to a two-stroke engine is to maintain primary compression. Condition of both piston rings and cylinder. Maintaining piston clearance. Depending on the model, this may include the tightness of the reed valves. In the case of 4-stroke engines, the most important point is the contact of the intake and exhaust valve seats. The maintenance to correct the valve seat contact condition = internal combustion machine processing is the intake and exhaust valve seat cutting and grinding.

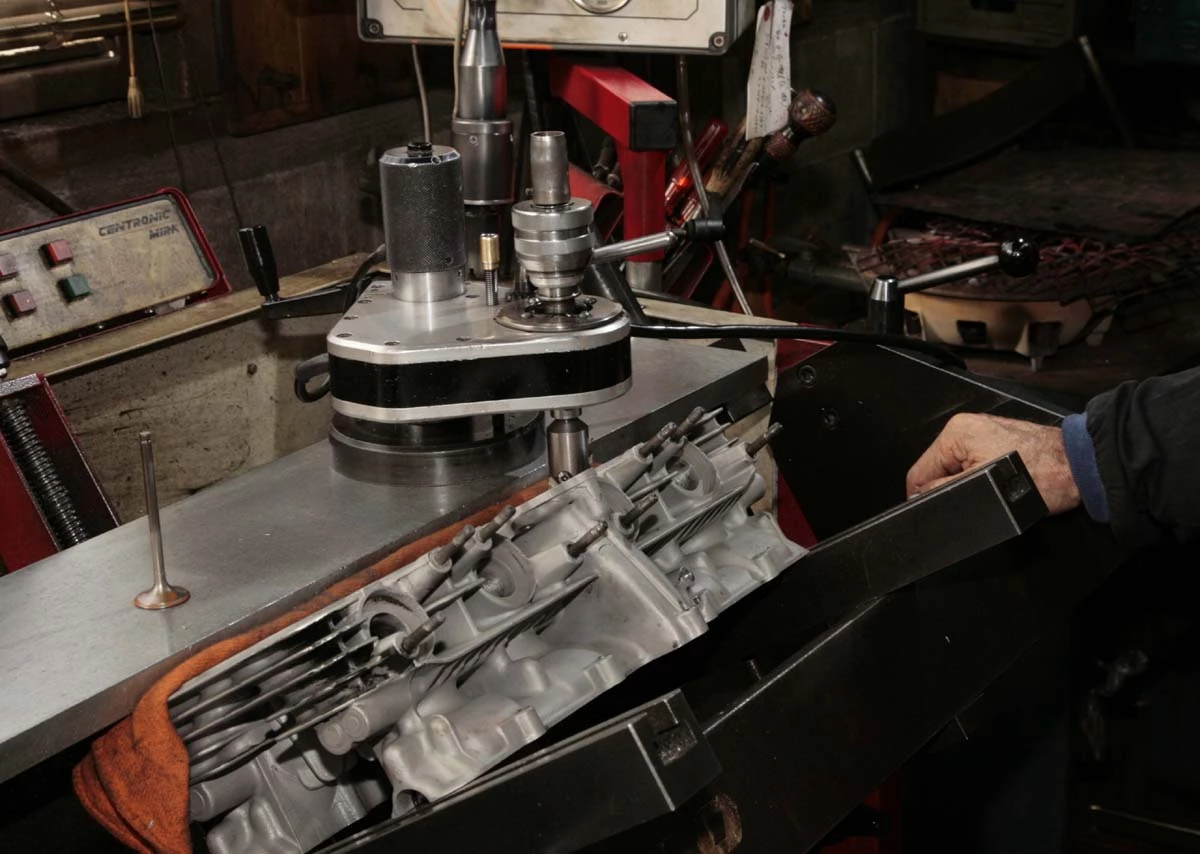

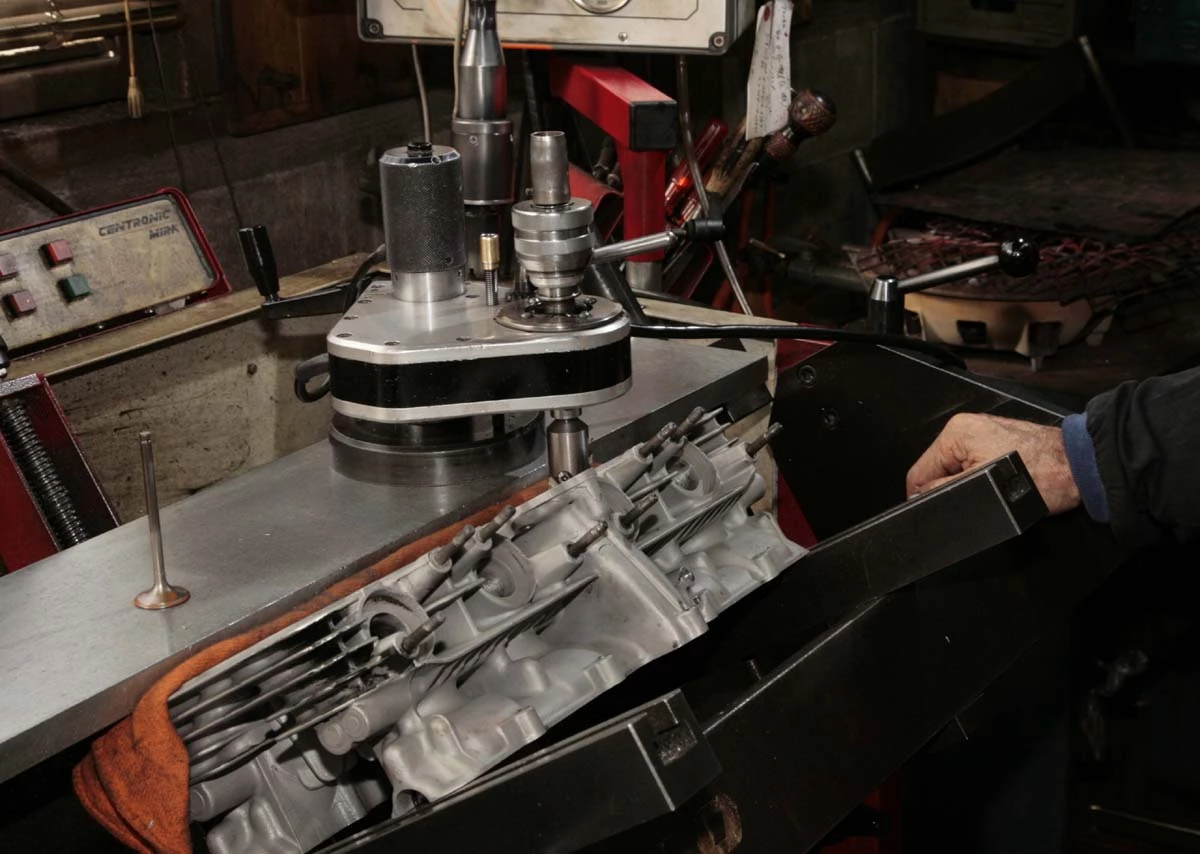

Face polishing to improve valve hit

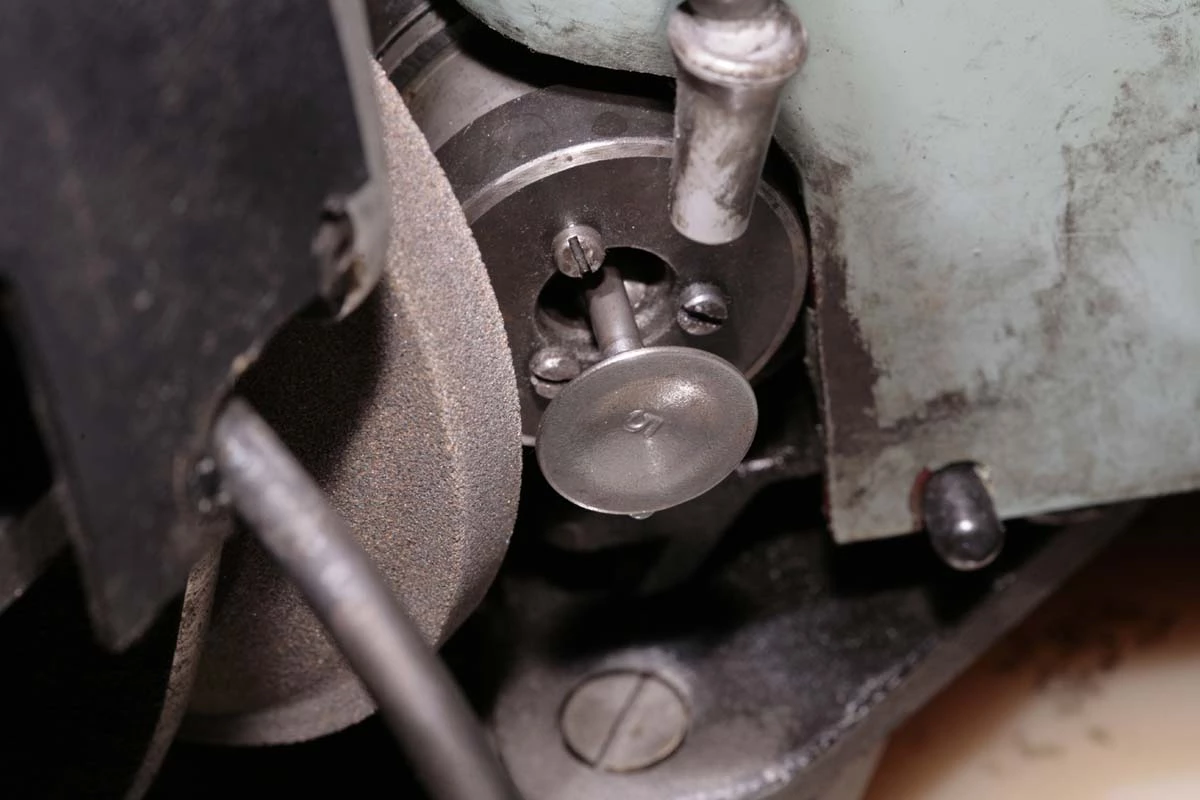

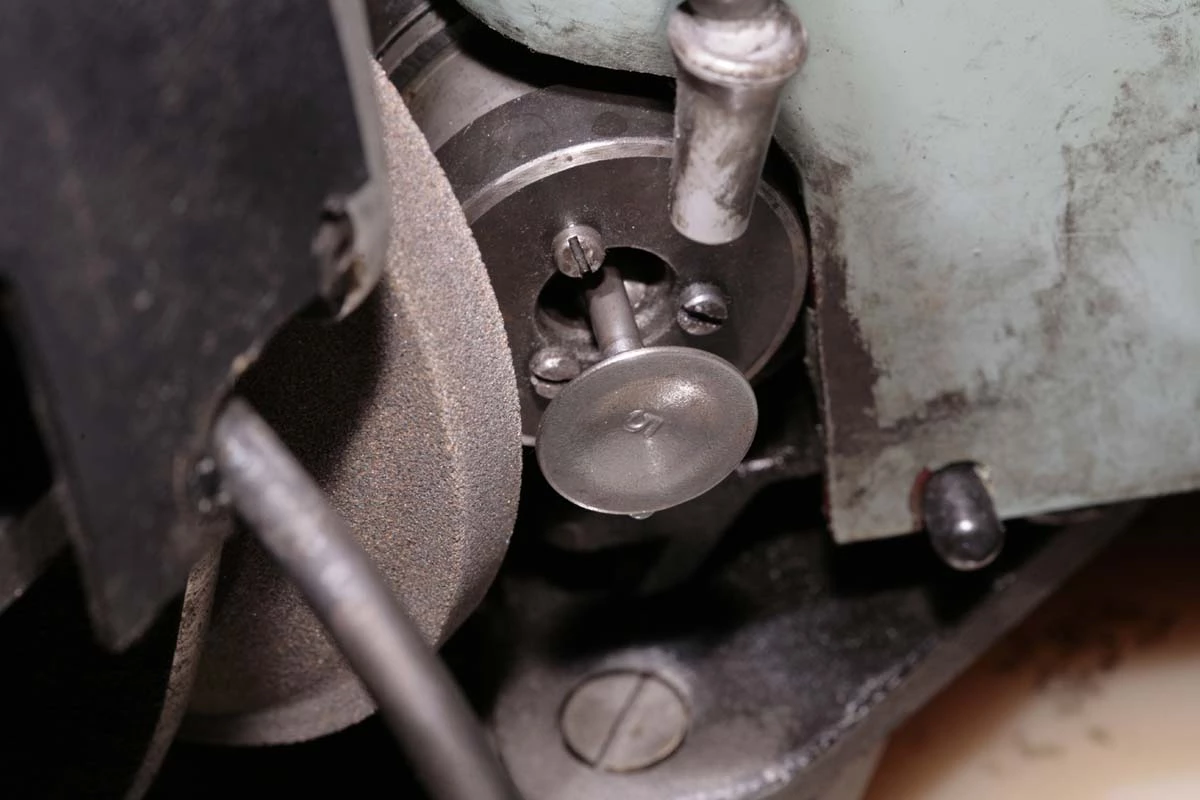

When we disassemble the cylinder head of an overdriven engine and remove the old exhaust valves, we find that the valve seat contact areas have become “pitted” to a greater or lesser degree due to wear. Under such conditions, the engine cannot perform as it should. Old exhaust valves that are in poor condition can be restored by internal combustion machining.

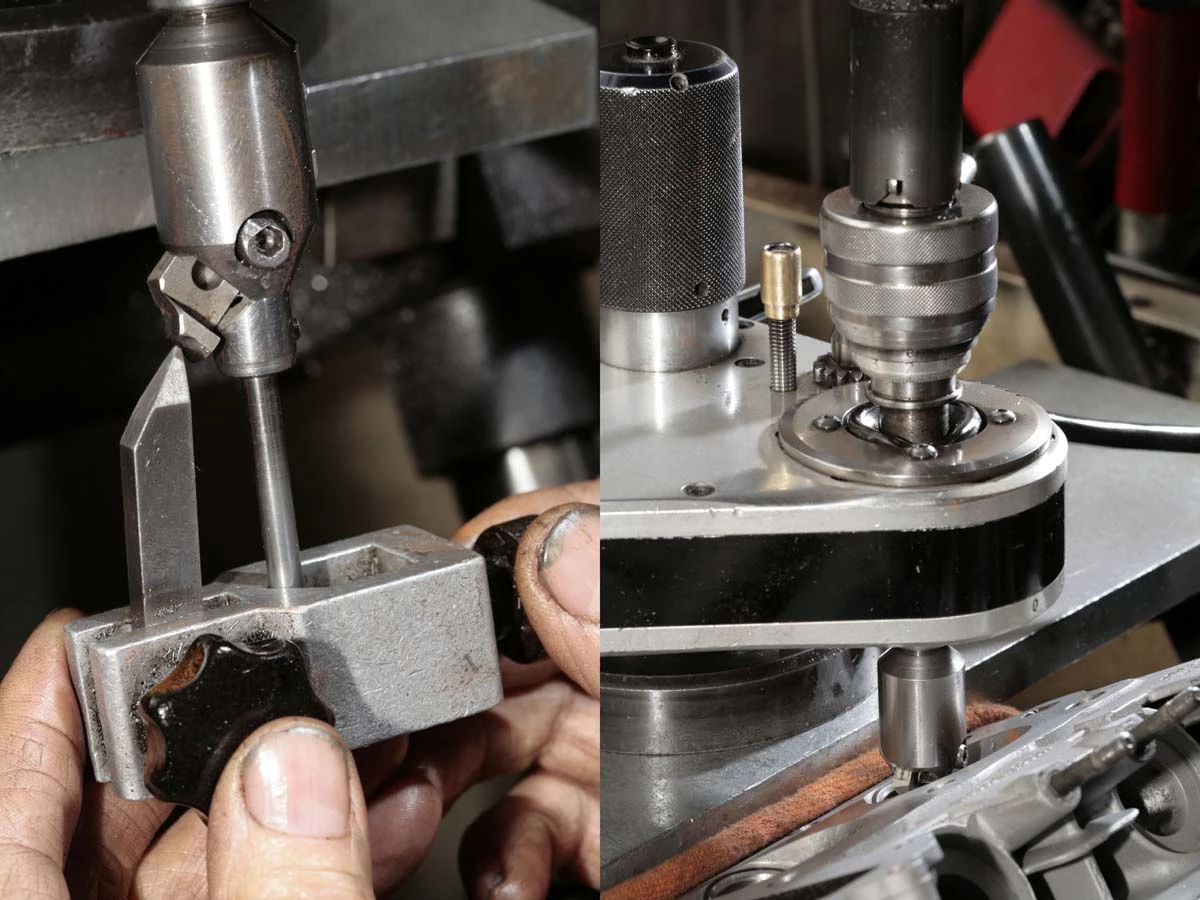

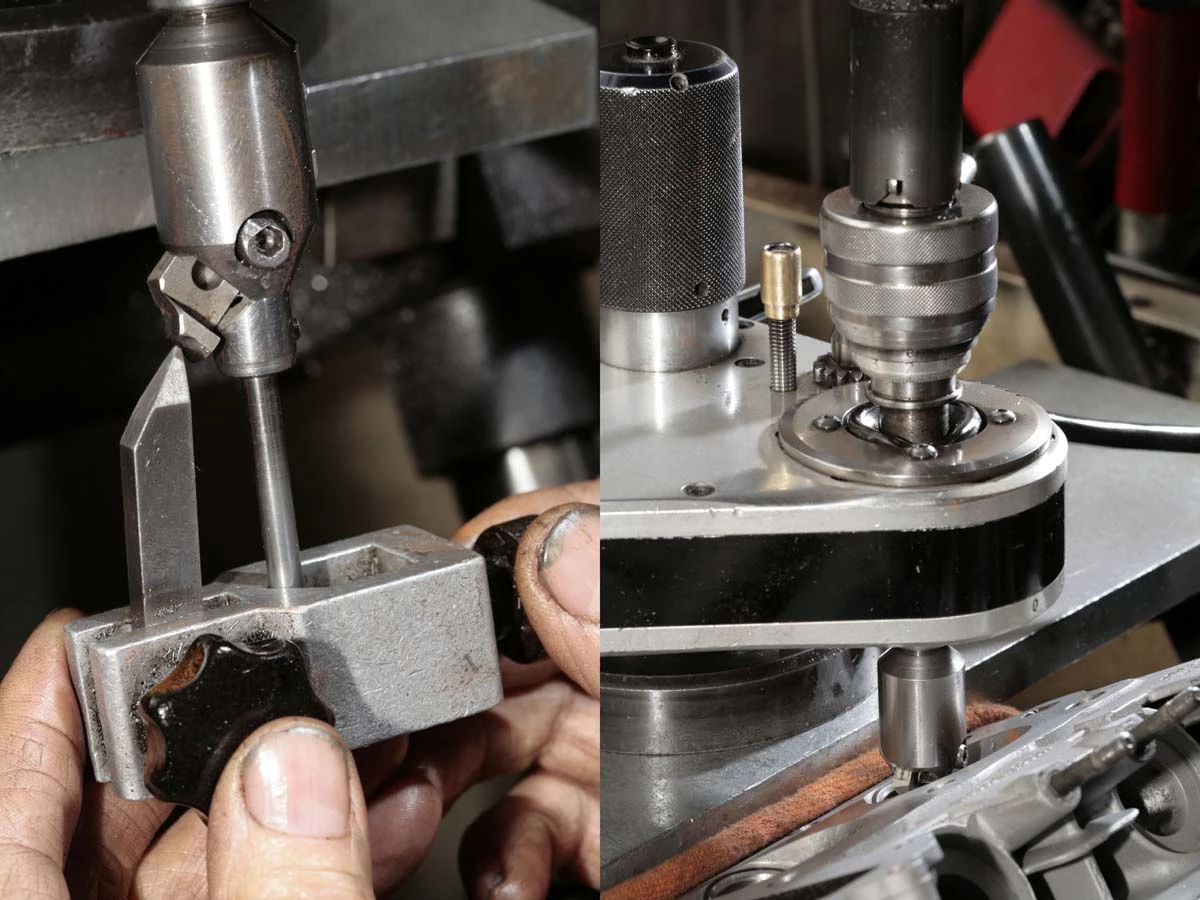

The face of the intake and exhaust valves is polished and regenerated by machining the valve seat face. iB Inoue Boring, which cooperated in the photo shooting, manufactured a jig for an American-made valve face polishing machine so that it can be used for Japan motorcycles. By grinding the valve seat, which is the position where the valve hits the exhaust, the machine polishes and reconditions the valve seat from a concave shape to a flat surface.

Seat cut to adjust the width of the valve hit

If you check the service manual (SM) issued by the manufacturer, the valve seat percussion angle and percussion width are clearly indicated. For small displacement and small-diameter valves, the contact width of 0.8 to 1.0 mm is often used, and for large-diameter valves, the contact width setting of 1.0 to 1.2 mm seems to be common. Especially for exhaust valves, some engine tuners dare to specify a wider hit width in order to allow the exhaust gas combustion heat to escape more easily. These numerical values are not determined by the internal combustion engine manufacturer, but rather by the engine tuner in charge of assembly. When oversized pistons are installed, boring and honing work is requested, and the piston clearance and other setting values specified at that time are also specified by the client.

When in doubt, consult an internal combustion equipment supplier.

Clear visual confirmation using red lead

The sheet-cutting work proceeded while checking the hit position with a vermilion mark called a red lead. For this exhaust valve, a hit width of 1.0 mm was specified, and the normal hit position was in the middle of the valve. In many cases, the width of the contact is set in the center of the exhaust valve, which is hot, in order to allow heat to escape more easily. The know-how in this area depends on the client’s (engine tuner’s) way of thinking.