Progressive cavity pumps are widely used in various industries for their ability to handle viscous fluids and maintain a steady flow. Understanding the pump curve is crucial for optimizing performance and ensuring efficiency. This article will guide you through the process of analyzing a progressive cavity pump curve.

Understanding the Progressive Cavity Pump Curve

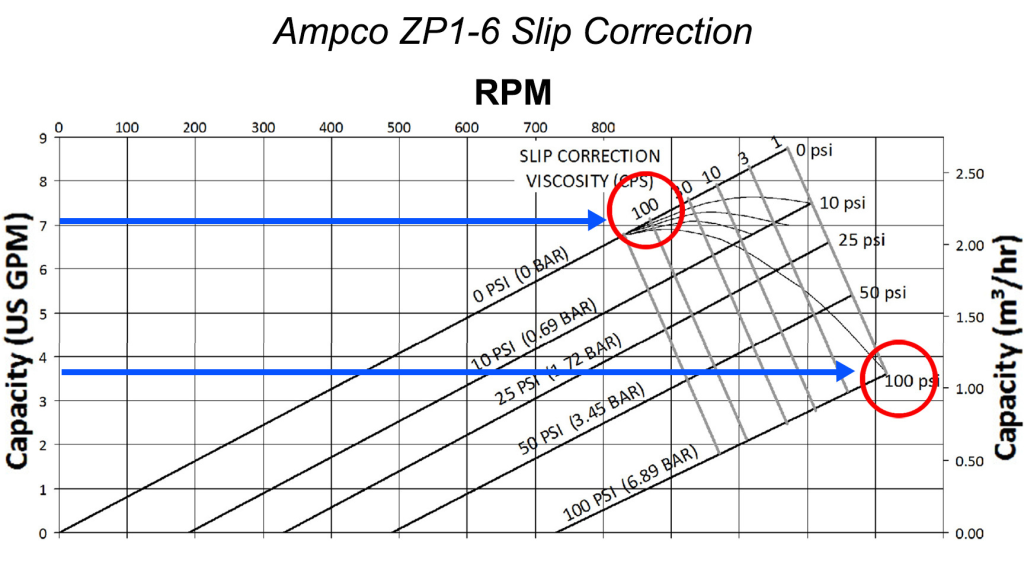

A progressive cavity pump curve typically represents the relationship between flow rate and pressure. It provides valuable insights into the pump’s performance under different operating conditions. Analyzing this curve helps in determining the pump’s suitability for specific applications.

Key Components of the Pump Curve

- Flow Rate: This indicates the volume of fluid the pump can move over a given time. It is usually plotted on the horizontal axis.

- Pressure: This reflects the pump’s discharge pressure and is plotted on the vertical axis.

- Efficiency: Often shown in a separate curve, efficiency indicates how effectively the pump converts input power into hydraulic energy.

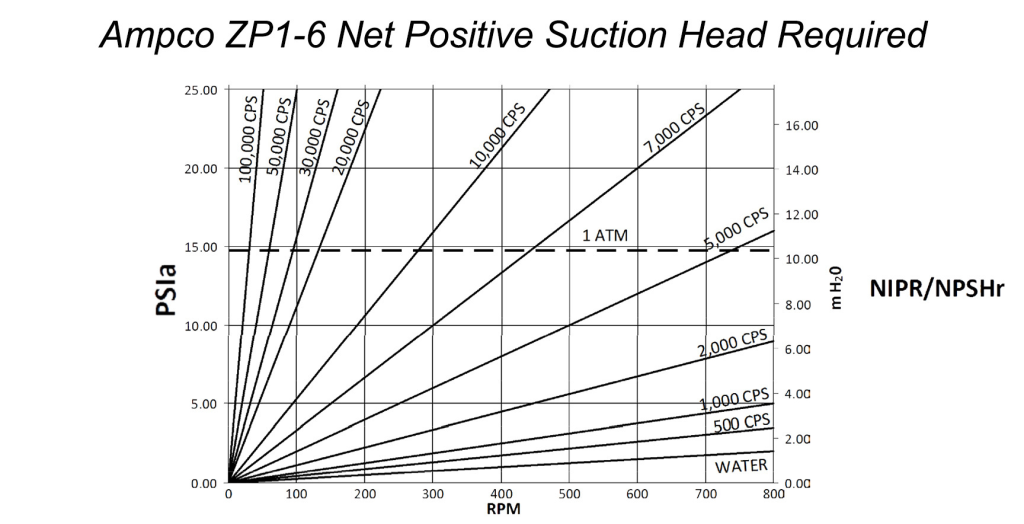

- NPSH (Net Positive Suction Head): This shows the minimum pressure required at the pump inlet to avoid cavitation.

Steps to Analyze the Pump Curve

1. Review the Axes

Start by examining the axes of the pump curve. Ensure that you understand the units and what each axis represents. Knowing the flow rate and pressure scales will help you interpret the data accurately.

2. Identify the Operating Point

Determine the desired operating point for your application. This point represents the flow rate and pressure at which the pump will operate most effectively. It is essential to select a point that lies within the pump’s best efficiency range.

3. Evaluate Efficiency

Check the efficiency curve. Aim to operate the pump at a flow rate that maximizes efficiency. Operating outside this range can lead to increased energy consumption and wear on the pump components.

4. Consider NPSH Requirements

Assess the NPSH curve to ensure that your system provides adequate suction pressure. Insufficient NPSH can lead to cavitation, which may damage the pump and reduce its lifespan.

5. Analyze Performance Trends

Look for trends in the pump curve. For instance, as flow rate increases, pressure may decrease. Understanding this relationship will help in troubleshooting potential issues and optimizing the system.

6. Compare Against System Requirements

Finally, compare the analyzed data against the specific needs of your application. Factors such as fluid characteristics, temperature, and system layout will influence the pump’s performance. Ensure that the selected pump meets all operational criteria.

Conclusion

Analyzing a progressive cavity pump curve is essential for ensuring optimal performance in various applications. By understanding its key components and following a systematic approach, you can make informed decisions that enhance efficiency and reliability. Proper analysis not only extends the life of the pump but also contributes to overall system effectiveness.